Levers

Levers are an essential part of many mechanical devices.

Levers enable us to transform forces and movements in a manner which we might not be able to do otherwise.

As Archimedes (also famous for "Eureka!") said: "Give me the place to stand, and I shall move the earth."

Operating Principle

The operating principle of a lever is mechanical advantage. Mechanical advantage enables a machine (including a human) to exert forces and move distances in a manner which would not otherwise be physically possible. This can be a force amplification, or a distance amplification.

Of course, there is no such thing as a free lunch. The work done (or torque) is always the same. In other words, for a lever, \( F_1 d_1 = F_2 d_2 \), where \( F_n \) is the force exerted at a given point on the lever, and \( d_n \) is the distance moved. In other words, Archimedes could move the earth, but very very slowly. But he could still move it.

All levers require three things to work: a fulcrum (or pivot), an effort, and a load. The relative placement of these things affects the class of lever.

Although the basic lever has only one lever arm, levers are frequently used in pairs joined at the fulcrum.

The diagram below shows the three classes of levers.

Class 1 Levers

Class 1 levers have the fulcrum between the load and the effort. Common examples include tongs, see-saws, pliers, scissors and crowbars (when used as a nail extractor). Class 1 levers are useful because they can enable a larger force to be exerted than would otherwise be physically possible. Class 1 levers are also useful because they can provide physical distancing between the effort and the load (e.g. with blacksmith's tongs).

Class 2 levers have the fulcrum at one end, effort at the other end, and the load in the middle. Common class 2 levers include wheelbarrows, nutcrackers and crowbars (when used as a lifting bar). Class 2 levers are useful because unlike class 1 levers, they can amplify a force without changing the direction the force is exerted.

Class 3 Levers

Class 3 levers have the fulcrum at one end, effort in the middle, and the load at the other end. Common class 3 levers include serving tongs, tweezers and hydraulic excavator arms. Class 3 levers are useful because the end moves a larger distance than the effort end moves.

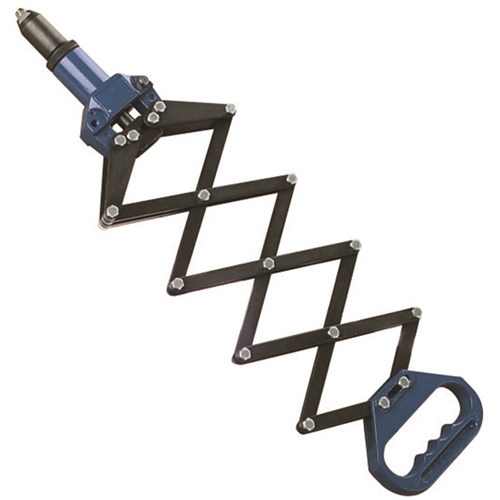

Compound Levers

Compound levers combine one or more levers. An example of this is an excavator arm. The first excavator arm segment (the arm closest to the cab) uses a class 3 lever. The second arm segment uses a class 1 lever.

Another type is a concertina or "lazy tongs" pop riveter. This uses multiple lever arms to amplify the force by a large amount, but still keeping it practical to use. It can be thought of a series of class 1 levers "folded in" on themselves.